Male-Female Standoffs were originally designed to fill a need around electronic device assembly, both during production and in-field repair. While spacers worked great to add support when stacking circuit boards, they had to be installed with a screw and nut. As multiple circuit boards were stacked, it would become difficult to get multiple spacers lined up for the screw to pass through all of them. In-the-Field repairs would often result in lost nuts and short circuits. Standoffs improved upon this as the screw was threaded directly into the standoff, but stacking could still be difficult. The Male-Female Standoff solved both problems as 1 part can work as a screw, spacer and nut. Damage from lost parts is greatly reduced. Circuit boards can also be easily stacked as each Male-Female Standoff is threaded into the next. With 1 fastener taking the place of the screw, nut, and spacer, many other industries began implementing this hardware into their products. These parts are now found in electronics, aerospace, medical devices, consumer goods and industrial designs.

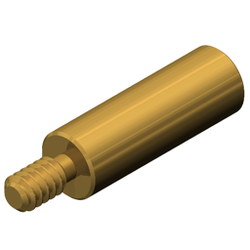

Male-Female Standoffs

Lyn-Tron's Comprehensive Buyer's Guide to All Things Male-Female Standoffs

Standoffs are used to separate, position or connect components in an assembly. Originally designed for spacing and stacking circuit boards, standoffs are now available in a wide variety of materials, platings, threads, and length combinations for different applications. Threads are compatible with other standard, Off-the-Shelf hardware, with custom threads available upon request. Common customization options include unique threads, custom lengths, and non-standard thread depths. Other changes are often easily incorporated into production.