Standoffs were developed as electronics evolved and became more complex in the number of components and circuit boards being used. Designers and engineers needed to add strength and rigidity to the assembly. Spacers were first used for this purpose and allowed for a screw to pass through the spacer and board and then being attached with a nut. This worked well when only stacking a few boards and/or doing smaller quantity production. When production volumes increased, standoffs were designed for faster assembly as they reduced the number of fasteners needed and made stacking several boards together more feasible. These same benefits were quickly picked up on by other industries and standoffs are now found in medical devices, aerospace, electronics, industrial designs, consumer goods and many other applications.

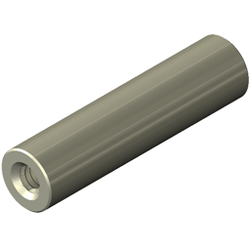

Female-Female Standoffs

Lyn-Tron's Comprehensive Buyer's Guide to All Things Female-Female Standoffs

Standoffs are used to separate, position or connect components in an assembly. Originally designed for spacing and stacking circuit boards, standoffs are now available in a wide variety of materials, platings, threads, and length combinations for different applications. Threads are compatible with other standard, Off-the-Shelf hardware, with custom threads available upon request. Common customization options include unique threads, custom lengths, and non-standard thread depths. Other changes are often easily incorporated into production.